How can Thermal Mapping help?

Thermal mapping provides a fast and cost-effective way to detect flaws in underground steam systems as well as hot and chilled water lines. This imagery provides valuable information to maintenance managers and decision-makers regarding the current status of these vital systems.

Steam Systems

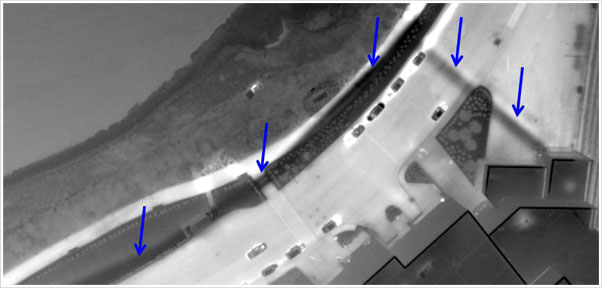

Underground steam lines are almost always readily visible from the air with infrared imaging, even when no notable problems exist. Through aerial infrared surveys, we are able to easily detect and pinpoint steam line faults, overheated lines, and line leaks.

Problem areas are generally quite evident, having brighter white infrared signatures that exceed the norm. Steam line faults normally appear as an overheated line or as a large hotspot in the form of a bulge or balloon along the line.

When there is a leak in the line, the whole conduit will visibly heat up with escaping steam. Some leaks may also show up as an overheated manhole or vault cover. Manholes or vaults that contain a steam system control apparatus connected to a faulty line will often heat the covers to warmer-than-normal temperatures.

Hot and Chilled Water Lines

High temperature hot water (HTHW), medium temperature hot water (MTHW), and low temperature hot water (LTHW) lines can be surveyed using similar methods to steam distribution and condensate return systems. Surveys can detect and locate line faults and leaks that would otherwise go undetected.

Chilled water supply (CHWS) and chilled water return (CHWR) lines are usually cooler than the surface temperature and can be surveyed for thermal loss and leaks as well.